High Quality Samarium Cobalt Large Industrial Strength Magnets For Sale

Professional Effective Fast

Product Details

High Quality Samarium Cobalt Large Industrial Strength Magnets For Sale

Smco Magnets manufacturer− Magnet Smco manufacturer − permanent Smco Magnet manufacturer

|

Material

|

Smco Magnet,SmCo5 and SmCo17

|

|

Size/Shape

|

Customized sizes,styles, designs,logo,are welcome

|

|

Thickness

|

Customize

|

|

Density

|

8.3g/cm3

|

|

Printing

|

UV offset printing/silk screen printing/hot stamping/special effects printing

|

|

Quotation Time

|

Within 24 hours

|

|

Delivery Time

|

15-20 days

|

|

MOQ

|

don't have |

|

Feature

|

YXG-16A to YXG-32B,Please refer to the details page for specific performance

|

|

Port

|

Shanghai/Ningbo/Shenzhen

|

Samarium–cobalt magnet) is also called samarium cobalt magnetic steel, samarium cobalt permanent magnet, samarium cobalt permanent magnet, rare earth cobalt permanent magnet, etc. It is a magnetic material made by mixing samarium, cobalt, and other rare earth metal materials, melting and refining them into alloys, crushing, pressing, and sintering. It has high magnetic energy product, extremely low temperature coefficient, and a maximum working temperature of 350 ℃, with no negative temperature limit. When the working temperature is above 180 ℃, its temperature stability and chemical stability exceed that of neodymium iron boron permanent magnet materials.

Has strong corrosion resistance and oxidation resistance; So it is widely used in aerospace, national defense and military industry, microwave devices, communication, medical equipment, instruments, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes, etc.

Product Display

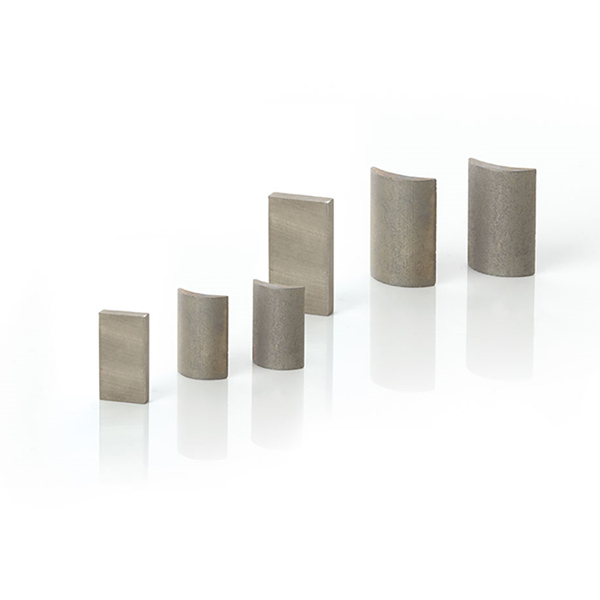

Advanced production equipment and 20 years of production experience can effectively help you customize various shapes! Special shaped magnet (triangle, bread, trapezoid, etc.) also can be customized!

>Customized Various Shapes Samarium Cobalt Magnet Magnet

Production and processing

Production process of Samarium–cobalt magnet: batching → smelting and ingot making → milling → molding → sintering and tempering → magnetic testing → grinding → cutting → finished products.

These alloys are usually processed in a non magnetized state. Samarium cobalt is finely ground using wet grinding (water-cooled heat dissipation) and diamond grinding wheels. This process is necessary if drilling or other functional limitations exist. Grinding waste must not be completely dried, as samarium cobalt has a low ignition point. A small spark, if produced with static electricity, can easily burn. The temperature generated by a fire can be very high and difficult to control.

>The Neodymium Magnet and Neodymium Magnetic Assembly we could produce

Note:Please see the home page for more products. If you can't find them, please contact us!

The above magnetic materials, magnetic components and magnetic toys are our best sellers, which are sold all over the world. With our excellent technology and trust, we are deeply loved by buyers. If you are also interested in our products, please feel free to contact us at any time.

Our Company

HESHENG MAGNET GROUP

As a professional magnets manufacturer, magnets supplier and OEM magnet exporter, Hesheng magnet specialized in R&D, production and sales of rare earth magnets, permanent magnets, (licensed patent) neodymium magnets, Sintered NdFeB magnets , strong magnets, Radial Ring magnets, bonded ndfeb magnets, ferrite magnets, alnico magnets,Smco magnets, rubber magnets, injection magnets, magnetic assemblies etc. Our factory has over 20 years' manufacturing experience in making magnets with different shapes, different coating, different magnetized direction, etc.

Processing and Production Equipment

Step : Raw Material→Cutting→Coating→Magnetizing→Inspection→Packaging

Our factory has strong technical force and advanced and efficient processing and production equipment to ensure that the bulk goods are consistent with the samples and to provide customers with guaranteed products.

Saleman Promise

Packing & Sale

Performance Table