Permanent NdFeB Magnet OEM ODM Special Shape Customized Magnet

Professional Effective Fast

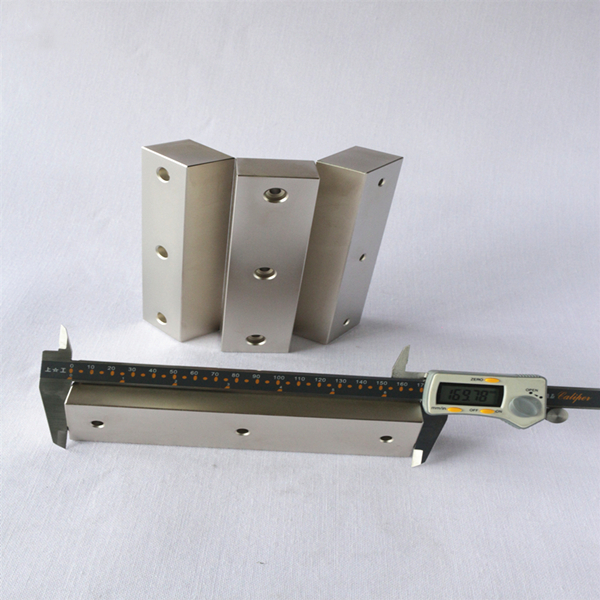

Product Display

Advanced production equipment and 20 years of production experience can effectively help you customize various shapes! Special shaped magnet (triangle, bread, trapezoid, etc.) also can be customized!

Our Company

30 years magnet manufacturer——Hesheng magnet group

it's mainly engaged in high-performance sintered NdFeB, samarium cobalt and other rare earth permanent magnets and magnetic tool products. Products are widely used in DC motors, permanent magnet generators, electronic appliances, instrumentation, sensors, mechanical equipment and other fields.

1) We are magnets with high precision

Tolerance can be controlled ± 0.03mm, even ± 0.01mm

2) Complete variety

A complete range of magnets can meet the needs of different customers

3) Assured quality

All magnet products comply with ROHS standards

4) After sales guarantee

Ensure magnet quality, production process and after-sales service

Processing and Production Equipment

Our factory has strong technical force and advanced and efficient processing and production equipment.

Quality Inspection Equipment

Excellent quality testing equipment to ensure product quality

Complete Certificates

Note: Space is limited, please contact us to confirm other certificates.

At the same time, our company can carry out certification for one or more certificates according to your requirements. Please contact us for details

Saleman Promise

Packing & Sale

Hesheng Group Reminder:

How to avoid magnet corrosion?

Compared with ferrite and other permanent magnet materials, neodymium magnet (NdFeB magnet) has excellent magnetism and is also the most commonly used rare earth magnet. It is widely used in electronics, power machinery, medical equipment, toys, packaging, hardware machinery, aerospace and other fields. However, neodymium magnets (NdFeB magnets) are very susceptible to corrosion. So how to avoid the corrosion of neodymium magnet? There are the following general methods:

1、 Phosphating

Phosphating is a process of chemical and electrochemical reaction to form a phosphate chemical conversion film. Phosphating has the following purposes:

1. Protect the base metal from corrosion to a certain extent.

2. It is used as primer before painting to improve the adhesion and corrosion resistance of the film.

3. It plays the role of friction reduction and lubrication in the process of metal cold working.

2、 Electroplating

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of other metals by electrolysis. The electroplating process is the process of using electrolysis to attach the surface of metals or other materials to a metal film, so as to prevent metal oxidation (such as corrosion), improve wear resistance, conductivity, reflectance, corrosion resistance and enhance aesthetic effect.

3、 Electrophoresis

Under the action of electric field, charged particles move towards the electrode opposite to their electricity, which is called electrophoresis. The technology of separating charged particles through different velocities of charged particles in an electric field is called electrophoresis. Electrophoresis is one of the anti-corrosion surface treatment technologies widely used in sintered Nd-Fe-B and bonded Nd-Fe-B permanent magnets. The electrophoretic coating not only has good adhesion to the surface of porous magnets, but also has the characteristics of salt spray, acid and alkali corrosion resistance.