Anti Scratch Car LED Camera Mount Hold Rubber Coated Pot Magnet

Professional Effective Fast

Anti Scratch Car LED Camera Mount Hold Rubber Coated Pot Magnet

Over the last 15 years Hesheng export 85% of its products to American, European, Asian and African countries. With such wide range of neodymium and permanent magnetic material options, our professional technicians are available to help solve your magnetic needs and choose the most cost effective material for you.

Product Details

|

Product Name

|

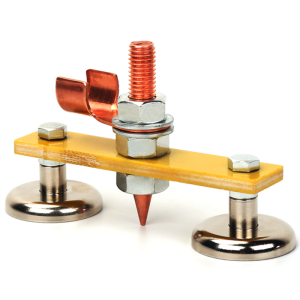

Rubber Coated NdFeB Pot Magnet

|

|

Materials

|

Strong neodymium magnet+Environment friendly rubber

|

|

Surface Treatment

|

Rubber seal lagging

|

|

Magnetic Grade

|

N52

|

|

Working Temprature

|

≤80℃

|

|

Delivery Time

|

1-10 working days

|

|

Common Diameter

|

22 31 36 43 66 88

|

|

Customized size

|

Available

|

D88mm 42kg 92lb Rubber Coated Neodymium Magnet With Threaded Hole

Rubber coated magnet, also referenced as rubber covered magnet or weatherproof magnet, is mainly made by sintered Neodymium magnet, stainless steel plate, and durable rubber coating.

This rubber coated mounting magnet is another new, water resistant design, It allows for easy mounting with a common screw.

The best feature of these magnets is their high-friction rubber coating. When mounting objects to a vertical surface (i.e., a steel wall), these magnets are great for holding up objects without excessive or expensive magnetic strength.

Excellet Strength Value: The highest(BH)max reaches up to 51MGOe

Our Company

HESHENG MAGNET GROUP is a professional MAGNET company with more than 30 years’ experience in magnetic materials and assemblies specialized in manufacturing, combined with R&D, production and sales. Meanwhile, we are also committed to customize high precision NDFEB MAGNET.

We have the complete quality system such as ISO9001,ISO14001and IATF16949. Also our experienced senior technical engineers can offer customers the professional technical solution and custom-designed service on our products. Our company’s main products are ndfeb magnets, hook magnets, fishing magnets, magnetic parts and etc, they are widely used in our daily life and industry area. We are confident to provide you with our best service from price, lead time and quality areas.

Processing and Production Equipment

Step : Raw Material→Cutting→Coating→Magnetizing→Inspection→Packaging

Our factory has strong technical force and advanced and efficient processing and production equipment to ensure that the bulk goods are consistent with the samples and to provide customers with guaranteed products.

Packing

Saleman Promise

Usage

Chat Now